What is a labeller?

Labelling equipment is manual, semi-automated or automated machinery that performs the process of applying a label to a product or package. The label is the most important design and information element of the packaging. The result of subsequent sales figures depends heavily on the appearance of the label and the quality of its application. With the help of labelling machines, the labels can be applied to the desired places, whether all-round, corner or 2-sided labelling – there are no limits to the possibilities.

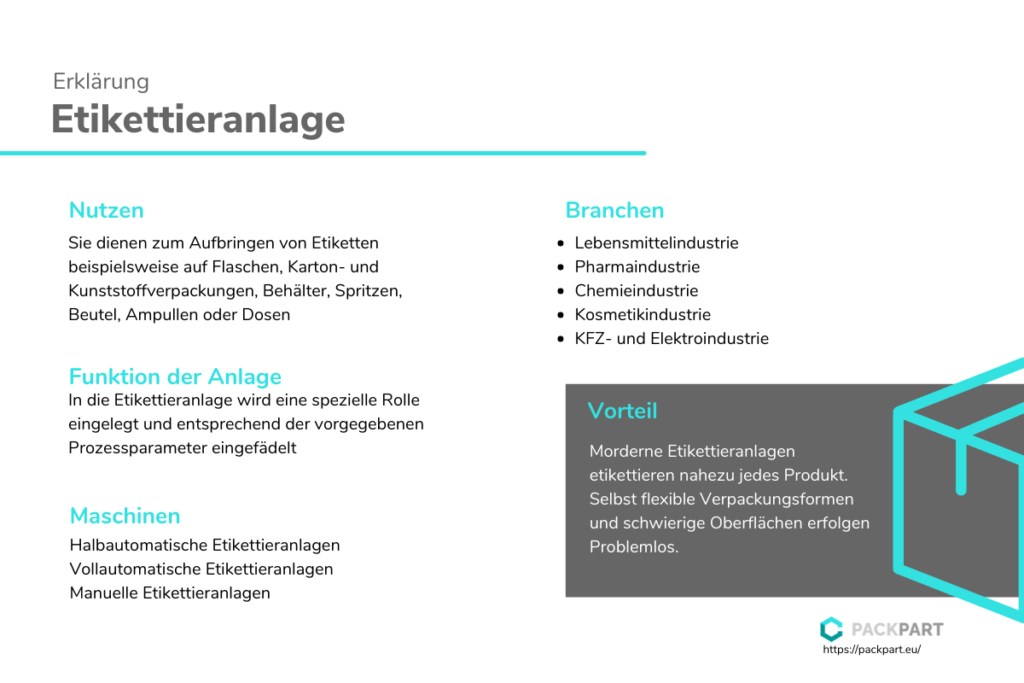

Labelling machines are used to apply labels, for example, to bottles, cardboard and plastic packaging, containers, syringes, bags, ampoules or cans. The configuration of the machines depends on the location to be labelled and the type of label. Labelling machines can be equipped with several labelling stations of different types. Modern labelling machines are modular in design. This makes it possible to exchange individual labelling stations quickly and conveniently.

Which synonyms are often used?

Many synonyms are used for labelling equipment, despite the same mode of operation. Widely used are terms such as labelling systems, labelling machines, labelling cells as well as automatic labelling machines.

Semi-automatic or fully automatic labelling systems? What is the difference?

Semi-automatic labellers are used for fast and precise labelling of small to medium product output and seasonal goods. Although such machines, in contrast to fully automatic labelling stations, require manual loading of the labelling device with products, they offer an increased degree of automation while reducing time and personnel resources (labeller-semiautomatic). Compared to the latter, automatic labellers are directly integrated into the production process and unfold their full potential in continuous labelling runs with medium and large product batches (rotary machine). In addition to semi-automatic and fully automatic labellers, there are also manual labellers such as price labellers, which are well suited to mobile labelling for smaller batches.

Semi-automatic labelling systems

Companies with small or medium production volumes prefer to use semi-automatic labellers. The use of such a machine requires human intervention. Usually, the operator’s task is limited to bringing the goods to the labeller and placing them in a special area of the machine. The machine is then set in motion via a control element and a label is applied.

Such labellers are easy to use and apply the label precisely. This is particularly advantageous when the label is large or needs to be applied to a cylindrical object. There are different types of semi-automatic labellers:

- For products with straight edges – the applicator only applies the label to a flat surface and is well suited for boxes as well as rectangular bottles.

- For cylindrical items – a special labelling roller reliably applies the label to a curved surface on bottles or cans, for example.

- Universal – with such machines, the shape of the object is not important.

Fully automatic labelling systems

.

Fully automatic labellers handle the entire process of labelling and are ideal for large production volumes. To automate the entire cycle, the labeller must be equipped with a label dispenser. In many models, a hot printer or thermal transfer printer is also integrated for printing on film. The labels are fed through a special roller conveyor and aligned on the rollers according to the specified parameters before being applied. A built-in photo sensor takes over the control of the correctness of the labelling. Defective or damaged stickers are removed automatically. The labeller is controlled by a uniform control system. This system is used for targeted and continuous monitoring of the process.

How does a labelling system function?

A special roll is inserted into the labeller and threaded according to the specified process parameters. The label can either already be printed or it is printed inside the labeller with the aid of a print module.

On manual machines, the label is applied to the product by hand. In semi-automatic and fully automatic labelling machines, this process is automatic.

The label can be applied according to different procedures:

- Tamp-on labelling via the corner – the label is stamped onto the product by a dispenser arm.

- Blow-on labelling – the label is applied by compressed air without contact.

- Tamp-blow labelling – the label is first positioned, then blown off with compressed air.

- Wipe-on labelling – the label is wiped off with the aid of a roller or brush.

Modern labelling systems can label almost any product. Even with flexible packaging shapes (e.g. bags) and difficult surfaces (oily, rough, etc.), labelling is carried out without any problems.

In which industries are the labellers used?

To meet different requirements from the industrial sector, manufacturers of labelling systems today offer application-specific solutions that can implement almost any labelling task. In this way, companies benefit from highly reliable and robust machines that can be integrated smoothly into the packaging and labelling process. Labelling systems have become indispensable in many fields of application, including palletising stations and packaging lines, and are represented in almost all branches of industry, such as food, pharmaceuticals, chemicals, and the automotive and electronics industries.

Types-of-labelling-systems

Bag labelling machines

Bag labellers allow bags or other flat products to be labelled quickly and precisely on the top. In addition to bags with a zip closure or flat or side-folding or block-bottom bags, magazines, books, etc. can also be labelled. With the aid of an alignment aid, the product is brought to a stop and fed to the labelling belt in an aligned position. Gummed tapes hold the bag in place and make the process more precise.

Bucket labellers

.

Bucket labellers can be used to label buckets or other round products/packaging quickly and accurately on the top or all around. The labeller is adapted to the exact labelling specification. Special systems are used to align the pail and move it into the desired position. Handles, for example, can be taken into account in the alignment by means of individual position detection. The label is applied in the subsequent labelling station.

Canister labelling machines

With the canister labeller, canisters or other angular products/packaging materials can be labelled quickly and precisely on the outer surfaces or all around. The labeller is adapted to the precise labelling specification. Special systems are used to align the canister and place it in the desired position. Specifications in the application of the label can be taken into account by means of individual position detection in the alignment. The label is applied in the subsequent labelling station.

Carton labelling machines

The carton labelling machine is designed to label a carton. The special feature is that cardboard boxes come in a wide variety of heights or sizes. Carton labelling machines are specially designed to handle this difference in size. Labels can be applied to any surface, individually or across corners. The detailed orientation can be easily determined.

Industrial labelling systems

.

In particular, the labelling of industrial goods requires specialised labelling equipment. Industrial goods come in all shapes and sizes. The labelling process is correspondingly demanding. Special solutions for labelling around the goods simplify your process. A wide variety of methods for applying labels can be integrated into the process.

Bottle labelling systems

.

The labeller is built to match the bottle in question. It can be labelled all around, the sides or even the lid. Depending on the customer’s wishes, many things are possible here.

Can labeller

Since cans are usually round and made of metal, you need a wrap-around labeller. This can also be used to label a metal surface without any problems.

Ampoule labelling machine

.

Ampules are very small, so the labeller must be designed specifically for these small containers.

Tube-labeller

.

The tube is labelled either by applying the appropriate label or by using a sleeve. Labelling is a little difficult here because the shape of a tube is not so easy to label.

Sleeve labelling machines

.

This is a sleeve film that already has the desired print on it. This film is then pulled over the container and shrunk or sleeved by heating. The film adapts perfectly to the container and decorates it with the desired print.