Filling machines are used across all industries and enable fast and efficient filling of containers. The modern machines not only offer a wide range of possibilities, but can also be specially and individually adapted to the needs of customers.

What is a filling line?

Filling lines and filling machines fill individual packaging units with liquid, paste and powder form. There are a large number of different sub-types of filling equipment. These are mostly special machine solutions adapted to specific customer needs. These solutions are geared to the conditions of the packaging material and the product to be filled. Based on the packaging material and the requirements of the filling products, a specific filling or dosing type is defined together with the customer and the consulting filling equipment manufacturer.

The following filling and dosing types are widely used in modern industry:

- Undermirror filling – is used for foaming products such as beer

- Transom filling – is suitable for unproblematic products, which are filled into cans or buckets

- Bottom bung filling –is suitable for filling goods that are filled into canisters or drums

- Vacuum filler – is generally used for pasty and highly viscous products with high quality requirements

Depending on the nature of the product and customer requirements, there are other filling technologies such as piston, rotary, weighing, time/pressure dosing. Today, filling processes are also supported thanks to built-in sensors for inductive flow measurement.

What synonyms are often used?

Many synonyms are used for filling equipment, despite the same mode of operation. Widely used terms are filling lines, filling machines, filling stations and automatic filling machines.

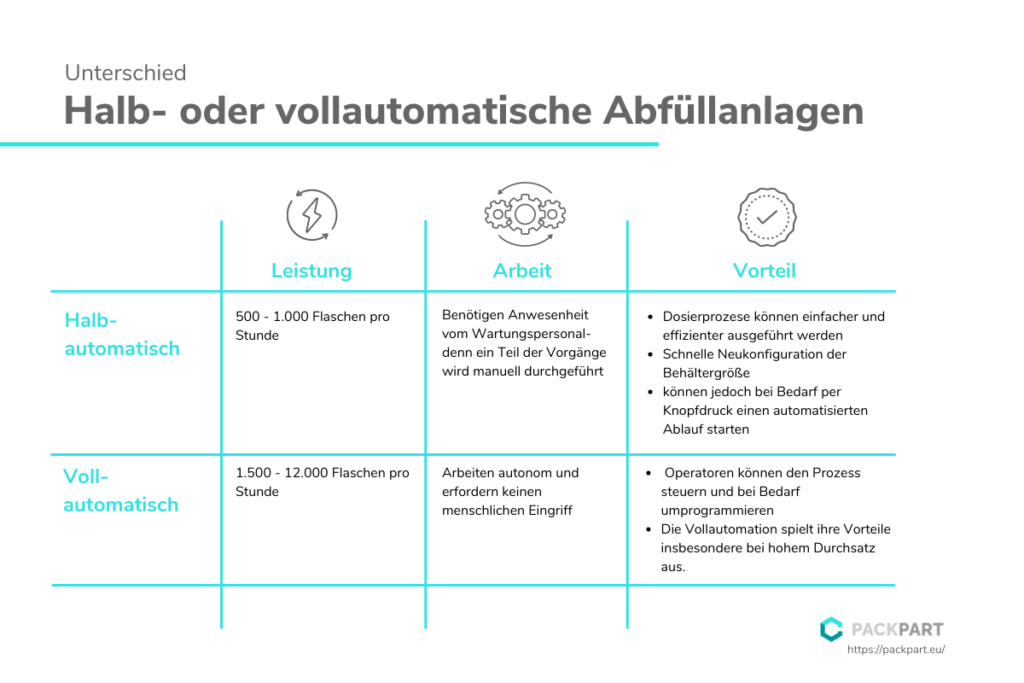

Semi-automatic or fully automatic filling lines? What is the difference?

Depending on the degree of automation, filling lines are divided into automatic, semi-automatic and manual. The fully automatic systems work autonomously and do not require human intervention. The semi-automatic filling systems require the presence of the maintenance staff – because part of the operations is performed manually. Manual filling systems are well suited for small batches and are widely used in the vegetable and fruit processing industry and research industry.

Semi-automatic filling lines

With the help of semi-automatic filling machines, dosing processes can be carried out more easily and efficiently. Such filling machines are suitable for both liquid and highly viscous products that require precise filling. Semi-automatic filling systems, unlike automatic ones, allow quick reconfiguration of the container size. Thanks to semi-automatic operation, machine operators benefit from a reduced workload, but can start an automated sequence at the push of a button if required.

Fully automatic filling lines

The main difference between an automatic filling line and a semi-automatic line is the overall output. For example, an automatic filling line can operate in a throughput mode of 1,500 to 12,000 bottles per hour a semi-automatic 500 to 1,000 bottles per hour. On a fully automatic line, all filling operations are performed without human intervention. However, operators can control the process and reprogram it if necessary.

Full automation shows its advantages especially at high throughput.

Manual filling lines

Manual filling machines are often used for small series or individual production. The manual filling machine has the finest mechanical dosing devices, which ensure a precise to exact filling quantity. If high throughput and repetitive production steps are required, the use of semi-automatic or fully automatic machines is recommended.

Types of filling equipment

A uniform classification of filling equipment is not possible today. This is due to an enormous variety of technologies, processes, packaging materials, a large number of filling goods and the use of the same technological processes for completely different product groups. The most important representatives of filling lines are listed below.

Big Bag Filling Line

The big bag filling line is an industrial filling station suitable for filling into light flexible containers. Today, the big bags are undoubtedly the most economical type of packaging for large-volume cargoes. They are successfully used in logistics systems for transportation and storage of bulk materials from chemical, agricultural, construction, food and other industries.

Bag filling line

The bag filling machine is explicitly designed for bag filling. These are flexible pouches that are filled with the product medium. This is a very sustainable solution, as during transportation an empty recyclable bag takes up much less space than a bottle or canister. These systems are well suited for any type of product, solid, liquid or powder.

Bag filling line

The bag filling machine is designed for filling bags. Sacks are usually larger and therefore require different designs than a bag. Such equipment is usually suitable for powdery or solid products, which can be filled into bags of different shapes.

Filling line for ampoules

Ampoule filling machine is specially designed for the small size of ampoule and provides fine and accurate filling. The best known examples are filling machines for eye drops, beauty products such as anti-aging and pharmaceutical products.

Cartridge filling line

Cartridge filling is a special type of filling. This subtype of filling machines is special because the filling of the cartridge takes place laterally and is usually not metered. Silicone, adhesive, etc., for example, is filled into cartridges.

Tube filling line

Tube filling is usually filled from the top and not before the cap is applied. This type of filling is well suited for filling products such as ketchup, mustard, mayonnaise, jam and glue.

Drum filling machines

Drum filling machines are suitable for liquid, viscous and pasty drum products. The products come from the chemical, food, pharmaceutical or other industries.

Bottle filling machines

These systems are used for filling bottled products. Fields of application come from almost all branches of industry. In the case of bottled products, filling is often quantity and volume controlled. Different measuring methods such as mass and inductive flow measurement are used for indication. The systems are suitable for all types of bottles, whether normal bottles, round bottles or waisted bottles.

Cup Filling Machine

A cup filling machine is specially designed for cup filling. Since cup products often come from the food sector (yogurt and dairy products), particular attention must be paid to compliance with hygiene regulations during filling. In addition, to meet the quality requirements for rapidly perishable goods, there must be virtually no exchange of air between the environment and the sterile chamber. Treatment with hydrogen peroxide can be useful for sterilizing the filling cups – these are then also referred to as Ultra Clean and Aseptic hygiene classes. To keep the machines clean, they have automatic cleaning programs such as Cleaning-in-Place (CIP) and Sterilizing-in-Place (SIP).

Can filling line

Filling into a can is similar to filling into a bottle. The difference from the bottle is only in the material and size. Typical products include, for example, cans of pineapple, tomatoes and peas.

Canister filling systems

A canister filling machine is suitable for liquid, viscous and pasty products. Canisters are containers with a capacity of between 2 and 60 liters, which are often larger than standard bottles. Canister filling machines have to fill large quantities of product in a short time with high accuracy. As a rule, canister filling machines have much larger filling tubes in order to be able to fill a given volume of product on time.

How does a filling line work?

Filling machines fulfill the task of filling containers of various shapes such as bags, sacks, bottles, cans, barrels and cups with liquid, paste and powder product media. The filling technology used in the machines always ensures a suitable quantity of product medium in the containers. In a piston filling machine, for example, the piston stroke is proportional to the filling quantity and can be set precisely to the required quantity. Other machines work with sensors for level measurement at the end of the filling tube or for inductive flow measurement and always ensure the exact quantity in the containers. Filling machines come in versions of linear and carousel filling machines. Carousel machines achieve higher outputs per hour compared to linear filling lines.

In which industries are the filling lines used?

Today, filling machines are an integral part of industrial container filling with liquid, paste and powder products. Today, filling machines are actively used in the cosmetics, food, pharmaceutical and chemical industries.

Cosmetics

Filling lines are used for filling cans with toothpaste, vials for beauty products, shampoos and creams for personal care.

Food

In the food industry, the best-known application examples include the filling of cup- and bottle-shaped containers with beverages, dairy products, and spices. The filling systems must comply with the applicable hygiene regulations.

Pharma

Similar to the food sector, hygiene regulations must be adhered to and contamination potential of the filling equipment minimized as far as possible in order to meet high standards in the pharmaceutical and medical sectors. Well-known examples of applications are various liquid, powdered pharmaceuticals such as eye drops and antibiotics.

Chemistry

In the chemical industry, thanks to filling systems, bottles or other containers are filled with chemical substances and compositions of substances. Especially in connection with chemical and aggressive substances, it is necessary to pay attention to the corrosion resistance of filling systems to such media.