What is a closing machine?

A sealing machine serves the purpose of sealing the packaged product in the packaging material after filling or packaging. This ensures that the product is protected from possible external influences by the primary packaging. Only when the closing machine closes the packaging material is the product protected and can be further processed or transported.

Closing machines can appear in different types. There is the main focus of screwing, where closures of containers are screwed by the capping machine. The pressing in & on is done in the same way. Here, no screwing is done, but the capping machine presses the closure into the container. Other key operations can include rolling and sealing.

Closing machines are available in various degrees of automation, in manual, semi-automatic or fully automatic variants.

What synonyms are used in professional circles?

The word “capper” is also frequently used as a synonym. A distinction is made between capping machines with a capping agent or capping aid and capping without a capping agent or capping aid.

The main difference is that in a closing machine designed for closing without a closing agent or closing aid, the packaging material is able to close itself. This characteristic is often found, for example, in packaging made of cardboard, paper or tubes. As a rule, these are inserted, folded, sealed or welded.

If closure means are to be used, the process of twisting or pressing on lids is behind it. The lid is directly connected to the packaging material. When used, the closing can be done by means of tying, clipping, stapling, gluing, soldering or sewing. Closing aids can be, for example, closure labels that protect against unauthorized or unintentional opening. Ensuring tightness may also require the use of sealing aids.

What are the types of capping machines?

There are many different capping machines. Each of these machines is precisely tailored to the user’s application.

Manual capping machine

The capping process can be manual, but is mostly integrated into a complete packaging line in the form of a capping device. Manual capping machines are mainly in demand for sealing, untwisting and vacuuming. In view of the manual handling, the output capacity of a manual capping machine has to be reduced. Manual capping often involves a great deal of physical effort.

Semi automatic capping machine

In the case of semi-automatic capping machines, the cap usually has to be placed manually, while a conveyor belt moves the packaging material with the cap in place towards the capping spindle, which tightly connects the packaging material and the cap by turning or pressing. During the closing process, a machine operator is indispensable, as he must actively accompany the closing process. Without him, the capping machine comes to a standstill.

Fully automatic capping machine

Fully automatic capping machines can be connected to feeders and upstream machines. As a result, the cap is automatically fed to the capping spindle. The capping spindle moves off and when pressure is applied, the screwing or pressure process is automatically triggered. Probably the best known is the classic screwing option for bottles or glass-like containers. This capping process is started once manually and can then be completely automated over several hours.

In which industries are the capping machines used?

Closing machines are used in any industry. They can be found in the food, chemical, pharmaceutical and cosmetics industries. Sealing machines are most often found in areas where a product must be linked to a packaging material and made durable.

Sealing machine in food industry

Bottle capping machines for the food industry are often equipped with a tamper-evident cap. Crown capping machines are also found in the food industry. Tin cans are crimped with the help of capping machines in order to be hermetically sealed. The most common types of bottles in the food industry are glass bottles or cans.

- Tin can seaming machine

- Bottle types

- Capping machine bottles

- Crown Cork Sealing Machine

- Bottles, jars, cans

- Bottles screw cap machines

- Capping machines for bottles

Capping machine in cosmetic industry

In the cosmetics industry, the most common packaging materials are jars, tubes and flacons. The most common capping machines are screwers and sealing machines. Closures with a riser tube, so-called dispensers, are also frequently used. The difficulty with these closures lies in the centering and insertion of the riser tube.

Capping machine in the pharmaceutical industry

Products that are closed in the pharmaceutical industry are e.g. vials, tablet cans etc.. Most often, capping machines are needed for screwing or crimping caps. A frequent emerging issue is closures with child safety locks.

Capping machine in chemical industry

Canisters, bottles, drums, etc. are indispensable in the chemical industry. For these containers, due to often corrosive, highly concentrated products, it is even more important that a capping machine closes the containers well and securely. With regard to cleaning agents, there is another special closure. The spray gun requires a capping machine with a special capping spindle. The reason for this is the position of the screw cap, which is very difficult to access through the spray head.

Types of capping machines

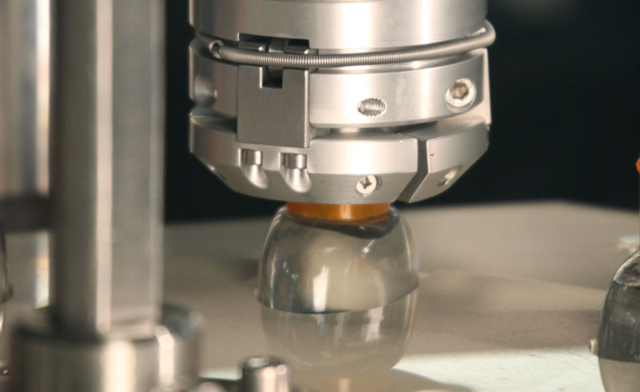

Capping machines for rolling

This type of capping machine is suitable for short rolling of a cap. No large torque is required to position the closure firmly on the container.

Closing machines for screwing

The capping machine type for normal screwing of screw caps can be suitable for a wide variety of cap types. It can be a very simple screwing of a normal cap but also a somewhat more complex matter. For example, when it comes to a spray gun that brings a riser tube.

Sealing machines for pressing in/on

The displacement machine for closures that are pressed in or on are, for example, for roll-on deodorants. Since with a Deoroller the ball must be pressed in. Or it concerns a wine, which gets a cork, this must be pressed in likewise. The capping machine does not screw anything, but simply closes the container by pressing in or pressing on a cap.

Sealing machines

Sealing machines are also a type of closing machine, as they close something. A wide variety of processes are used to close a container so that it is open when opened and cannot be closed again. The purpose behind this is, for example in the food sector, the longer shelf life of the products.