Flow wrapping machines are true multi-talents and can pack a wide variety of products quickly and reliably in bags. They are mainly used in manufacturing companies.

What is a flow wrap machine?

In a form, fill and seal machine, a tubular container (e.g. a plastic film) is already sealed during vertical or horizontal transport. This very versatile machine type is available in several compact versions for both manual and automatic operation. The combination of manual and automatic product feeding as well as bag set loading can further increase flexibility and throughput. Such machines are characterized by high performance and ease of operation. The packaging process is carried out by the machine processing flat film or even empty pouches, which are formed into a tube during the process and then filled and sealed.

What synonyms are often used?

Various synonyms are used for form fill and seal packaging machines. Widely used are terms such as form-fill-seal packaging machines, form-fill-seal lines, form-fill-seal packaging systems and film bag machines.

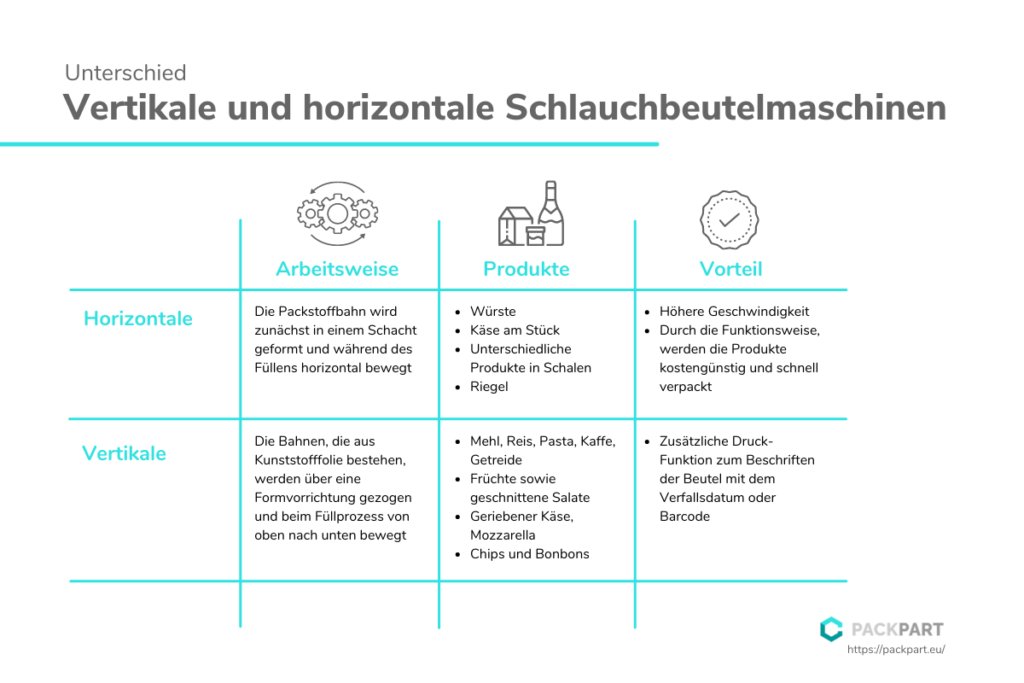

Vertical and horizontal form fill and seal machines – What is the difference?

A form fill and seal machine has two modes of operation. In the vertical mode of operation, the webs, which are made of plastic film, are drawn over a forming device and moved from top to bottom during the filling process. In the horizontal mode of operation, the web of packaging material is first formed in a chute and moved horizontally during filling.

Horizontal form fill and seal machines

Horizontal form, fill and seal machines are particularly suitable for the rapid packaging of individual or grouped products. The horizontal form, fill and seal machine solution is available in manual, semi-automatic or fully automatic versions. The difference to vertical form fill and seal machines is mainly the higher speed. The mode of operation of the horizontal form, fill and seal machines allows products to be packaged cost-effectively and quickly. The film is unwound from a roll, brought into the machine and advanced over the infeed rollers. With the help of the folding box the bag tube is formed, over which the product is transported in the bags. Sealing is performed either by the longitudinal sealing wheels or cross sealing jaws.

Typical products for the horizontal form fill and seal packaging machines are:

- Sausages

- Cheese by the piece

- Different products in trays

- Bar

Vertical flow wrapping machine

Vertical flow wrapping machines are ideal for packaging bulk materials, powdered products as well as liquids. Here, the film is unwound from a roll and fed into the machine via an infeed. The forming shoulder forms the film into a bag, which is sealed from all sides. As long as the upper opening is still present, the product is fed in via a special tube. After the desired amount of product is in the bag, it is sealed at the top. The modern vertical form fill and seal machines have an additional function of printing. This is often used for labeling the bags with the expiration date or barcode.

Typical products for the vertical form fill and seal packaging machines are:

- Flour, rice, pasta, coffee, cereals

- Fruits and cut salads

- Grated cheese, mozzarella

- Chips and sweets

How does a form fill and seal machine work?

The form fill and seal machine picks up pre-made individual bags from the special bag supply, stretches them and guides them to the filling station. After the bag has been filled with the desired medium, it is forwarded for sealing. The tubular bags can be equipped with resealing mechanisms such as zippers.

What packaging materials can be used with a form fill and seal machine?

In the age of smart materials and plastics, there are no limits to the materials bags can be made of. Today, a wide variety of materials are used for packaging, whether neutral, transparent, recyclable, thin or printed with a logo – almost all customer requirements can be met. Even the presentation of different film thicknesses from 40 to 150 µm, the production of oil-resistant films or those with special anti-corrosion coating is possible today. In this way, customers can select the appropriate materials for form-fill-seal bags for each form-fill-seal machine, taking into account product requirements as well as quality and environmental aspects. Uncoated or coated as well as paper-based composites of different shapes and types can also function as bag packaging and are becoming increasingly popular due to increased ecological awareness.

In which industry are form fill and seal machines used?

There are hardly any packaging requirements that cannot be realized thanks to the horizontal and vertical form, fill and seal packaging machines. These almost universal machines are able to process all types of bags. Fully automatic and semi-automatic machines are successfully used worldwide in industries such as food, cosmetics, chemical or pharmaceutical for the packaging of different product groups. The use in packaging of industrial goods with such machines is also widespread.

For which products is the form fill and seal machine suitable?

Form fill and seal machines are well suited for packaging any powdered and liquid products. For example, bakery products, confectionery and non-food products such as screws can be packaged sustainably, flexibly and economically efficiently in bags made from a flat film.