The term „Sustainability“ has long been on everyone’s lips. There is hardly a sector of the economy that can escape the trend reversal. The packaging industry has also been focusing on this topic for some time.

Already in 2019, Fachpack made a guest appearance on the keynote theme of “Sustainability in the Packaging Industry”. Companies are demonstrating their commitment to sustainability with entire website sections on sustainability.

What is sustainable packaging?

Sustainable packaging is made from recyclable and/or renewable raw materials and is also colloquially referred to as environmentally friendly packaging. The most important thing here is to use as few resources as possible. Therefore, both the amount of materials consumed and the amount of energy used play a major role when it comes to producing sustainable packaging.

Packaging manufacturers are rethinking functional packaging options not just for the sake of sustainability. Changes in production towards environmentally friendly packaging for the benefit of our blue planet and as a response to ever louder consumer demands are no longer uncommon. Sustainable packaging has really taken off in society.

A whopping 18.9 million tons of packaging waste was generated in Germany in 2018, according to the Federal Environment Agency (UBA). The frontrunners are paper waste and plastic. Paper and cardboard were recycled at 87.7 percent, while plastic was recycled at only half that rate.

So which packaging is the most “sustainable”? In principle, the recycling of resources comes before any packaging produced. There is nothing to add to this. Now, there are renewable raw materials that deserve a breather now and then, but there are also finite materials whose last days will come at some point. Therefore, the answer is quite clear: None!

No packaging means environmentally friendly and therefore sustainable consumption. However, since the so-called “zero waste” is far from being the whole truth, there are far more aspects to consider. To this end, it is worth taking a closer look at the functions of a packaging material:

What are the general functions of packaging?

Packaging is used for the efficient and orderly distribution of goods, it not only protects the product from external influences, but also partly protects the environment from the product itself (keyword hazardous goods). In addition, they ensure shelf life and ensure smooth transport. Packaging also serves to inform consumers about the best-before date or ingredients, for example. Last but not least, they contribute to the brand’s recognition value.

“What many people overlook: Packaging has great value for the environment. Packaging protects great values with relatively little effort. In the case of food, around 90% of the ecological impact comes from the food itself – and only 10% from the packaging.”

Deutsches Verpackungsinstitut

Besides, the packaging has various application functions, such as easy stacking, resealing ability, or good stability, etc.

The logical consequence is that goods without packaging are not always possible – or, to put it colloquially, packaging-free is not the “yellow of the egg” either. So what then?

The industry is taking a variety of paths to make packaging sustainable or more sustainable:

What sustainable alternatives are there to conventional packaging?

Biobased packaging

Materials that are produced from biomass, i.e. organic substances, are referred to as “biobased”. In the case of bioplastics, the biomass comes from renewable raw materials such as corn, sugar cane or cellulose.

In the case of bioplastics, although products are labeled “biobased,” they may be made only partly from biomass and partly from fossil raw materials (polymers). There is no clear definition and regulation here.

Packaging made from biodegradable plastics

“Biodegradability comprises the property of a substance to be decomposed by microorganisms in the presence of atmospheric oxygen to carbon dioxide, water, biomass and minerals, and in the absence of air to carbon dioxide, methane, biomass and minerals, with no time period defined. “This is the definition of the German Institute for Standardization (DIN) in 16208.

Here, “biodegradable” is not to be confused with “degradable.” The former describes decomposition into components found in nature, especially carbon dioxide and water. The latter refers to the weathering or decomposition of larger pieces of plastic into microplastics. In this form, it is barely visible, but no less harmful to the environment.

Compostable packaging

“Composting” refers to the same process occurring in fast motion under optimized conditions – that is, circumstances extra brought about by humans that do not normally occur in nature.

All compostable plastics are also biodegradable, but not all biodegradable plastics are compostable. Bioplastics labeled as “compostable” are not designed for compost in the home garden, but at best for industrial composting.

Conclusion: The combination makes the difference! Loosely based on the motto “good, better, best”, the complex of issues can be presented as follows:

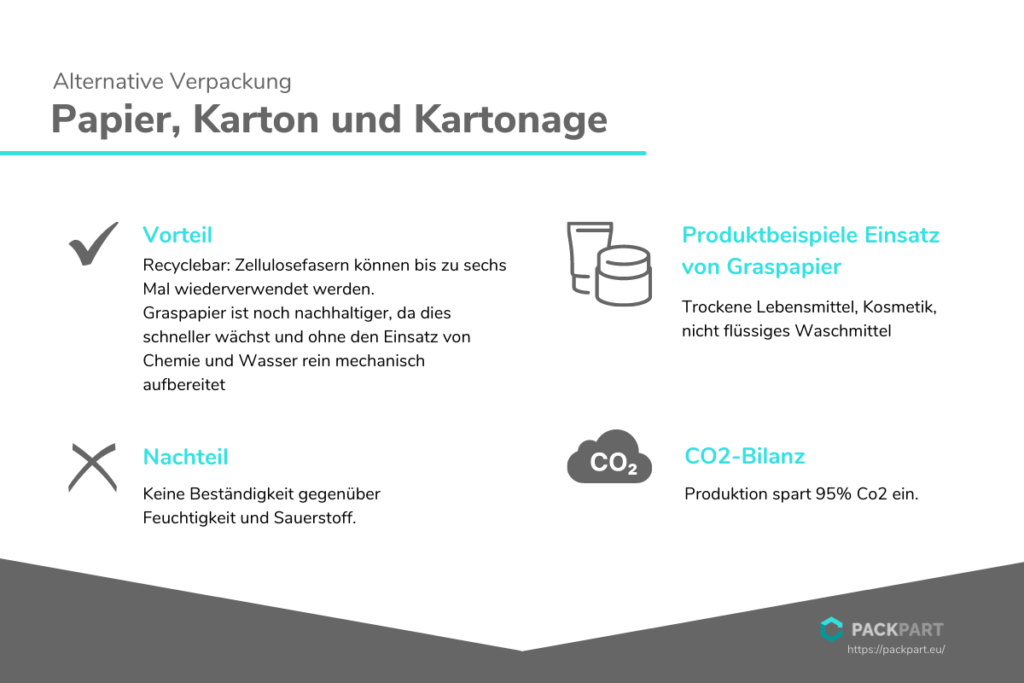

Paper, cardboard and paperboard

Recycling is the key to the success of wood-based packaging. Wood as an organically grown raw material forms the optimal basis for environmentally friendly packaging. The high recycling rate makes paper, cardboard and paperboard packaging the most popular sustainable packaging. Cellulose fibers can be reused up to six times! The diverse design possibilities of this packaging in particular speak in favor of the material. So wood is the basis for recyclable packaging

Disadvantage: Paper-based packaging material is not resistant to moisture and oxygen, which is why it is often found in combination with aluminum or plastics.

Corrugated board is even more sustainable and environmentally friendly than paper, cardboard or paperboard packaging. No trees have to be felled for its production.

Broken and thinned wood often form the basis of production. Glue, as an adhesive of natural origin, fixes the individual components.

As an absolute circular product in terms of recyclability, definitely worth mentioning in the sustainability ranking. In times of flourishing online trade, corrugated cardboard in particular has proven to be an addition to the carton. Where plastic cushions otherwise filled with air protected the products from breakage and damage, corrugated board takes over this task as an organic packaging material.

Grass paper rounds off the range. The principle: grasses grow back faster and in greater numbers than wood. Without the use of chemicals or water, the grasses are processed purely mechanically.

The CO2 balance is also impressive. Compared to virgin fiber pulp made from wood, production saves 95% CO2. Grass paper is also suitable for blending with packaging made from wood pulp. Up to 50% substitution is already possible today. Dry food, cosmetics, non-liquid detergents are product examples for the use of grass paper. However, the all-rounder should not be composted.

Sustainability increases with the recycling of the product, which means that this packaging should end up in the waste paper. Biological packaging material of a different kind!

Aluminum

Aluminum cans filled with soft drinks, the mustard tube, chocolate and so on. Aluminum is suitable as a barrier to oxygen and moisture, resistant to cold and heat, lightweight and recyclable.

Because of these properties, it is very popular as a packaging material for, among other things, food and kitchen utensils in the home. 2/3 of all aluminum residues can be recycled. Aluminum is not a renewable raw material. The aluminum packaging industry relies on recycling. About 75% of the aluminum produced to date is still in circulation today.

However, composite packaging, i.e. packaging in which aluminum is a component, still poses a problem in terms of recycling capability. The materials cannot be cleanly separated from one another. Printed aluminum packaging can release organic toxins when melted down.

Only 11% of consumers feel sufficiently well informed regarding the sustainability of packaging.

Result of a study by the strategy and marketing consultancy Simon-Kucher & Partners in March 2021

The weight advantage benefits transport in particular. Savings in CO2 due to lower emissions during transport increase the supposed attractiveness of the packaging. Industrial processors are constantly working to make aluminum packaging even thinner in order to minimize the amount of material required.

Even compared to plastic packaging, aluminum doesn’t look good. In contrast to plastic, recycling each ton of aluminum saves 0.1 metric tons of CO2 equivalents per ton of recycled material. On the other hand, the production of primary aluminum releases an average of 13.5 metric tons of CO2 equivalents per metric ton of primary aluminum. In plastics production, on the other hand, the figure is up to 2.4 metric tons of CO2 equivalents.

Only 11% of consumers feel sufficiently well informed about the sustainability of packaging. This is the result of a representative consumer survey of 1001 consumers in Germany on their attitudes toward and willingness to pay for sustainable packaging conducted by the strategy and marketing consultancy Simon-Kucher & Partners in March 2021.

Understandably, after all, it is enormously difficult to divide packaging materials into black and white. Every “for” is followed by a “against.

Here come our recommended actions for three of the most sought-after everyday products:

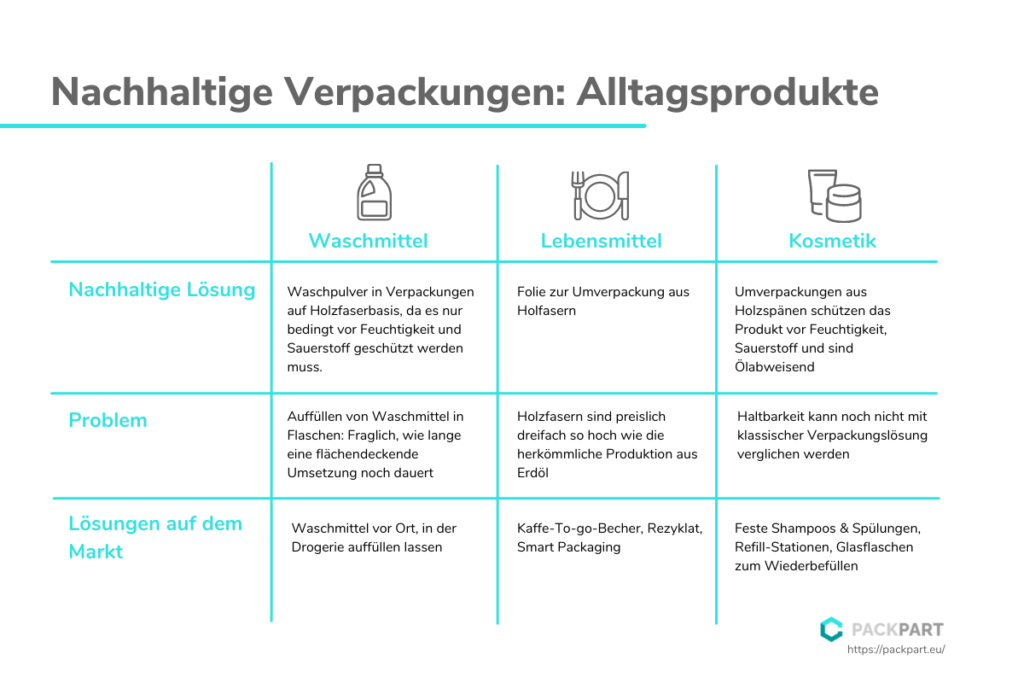

Sustainable packaging for detergents

Detergent: Reusable instead of disposable! The market for laundry detergents is now being shaken up by reusable models. The first drugstores are sporadically testing the offer of having the bottle practically refilled on site. This strategy is similar to that of “unpacked stores.

However, it is questionable how long nationwide implementation will take. Washing powder can be offered in wood fiber-based packaging without any problems. It only needs to be protected from moisture and oxygen to a limited extent.

If we look at liquid detergent, it is currently mainly filled in packaging made of bioplastics. It should be noted, however, that biobased and biodegradable variants are rarely represented, which is why they should not be purchased.

Sustainable packaging for food

Food: Probably no material comes into closer contact with food than packaging. With the task of protecting food from external influences, ensuring shelf life, and providing consumers with important information, such as indications of incompatibilities, food packaging plays a key role.

Not all foods can be produced and transported without packaging. Today, there are already possibilities to produce film for outer packaging from wood fibers. However, at three times the price of conventional film production from petroleum.

For this reason, wood fiber film cannot yet be fully integrated to cover costs. According to studies, consumers are willing to pay a certain additional price for ecological packaging, but practical implementation has not yet been tested.

Bioplastic variants should also be avoided in the food sector. The basic idea is on the right track, but still needs time to be fully thought through. However, combined with the multiple use of bioplastic containers (coffee to-go cups), for example, bioplastics could represent a real alternative.

Vacuum packaging, so-called smart packaging, saves packaging material by omitting oxygen. Sealpac GmbH in particular has made a name for itself in the field of sustainable packaging. Meat and other fresh produce can not only be presented appetizingly, but at the same time prolongs shelf life.

A hot topic in the packaging industry is the principle of “recyclate”. High-quality recyclate is extremely valuable. This is because recycled plastic, which is well processed and particularly pure, is hardly distinguishable from virgin material, but is not yet available in sufficient quantities.

In addition, recyclate is more expensive than freshly mined plastic from fossil sources. For now. Because the more recycling becomes the standard, the more the costs fall. Recycled plastic has been the talk of the town ever since a major grocery chain began advertising the fact that it replaces at least 50% of the material in its water bottles with recycled material.

Sustainable packaging for cosmetics

Cosmetics: In the beauty industry, it is no longer enough to process only plant-based ingredients to create a green image. Packaging made of wood chips protects the product from moisture and oxygen and is oil-repellent. However, their durability cannot yet be compared with classic packaging solutions.

Shampoos and conditioners can be purchased area-wide in solid condition. Packed in small cartons, plastic bottles have had their day. Because they are so easy to use, refill stations can be found in many non-packaging stores and drugstores.

Even recyclable bottles made of paper can be used well in the cosmetics sector. Well-known manufacturers developed these together with a Danish company. Especially the use of glass bottles for refilling thanks the environment.

The Packaging Act – What obligations apply to manufacturers and distributors?

Politicians are also urging packaging machine manufacturers to be more binding with regard to recycling. The new Packaging Act came into force in 2019 and replaced the Packaging Ordinance.

Packaging law 2019

The Packaging Act of 2019 is intended to increase the proportion of reusable beverage packaging and ensure that packaging waste is collected even more often close to households in the future. The Packaging Act establishes numerous obligations for online retailers, experts and other bodies. Fines of up to 200,000 euros could be issued for violations. The Packaging Act regulates the following:

Extended definitions

The definition of individual terms relating to packaging was largely taken from the Packaging Ordinance. The basic content was the clarification that shipping packaging is also considered sales packaging. This has the effect that online retailers are also required to participate. The term “reusable packaging” was also defined.

Increase in recycling rates for packaging

Previously valid minimum recycling quotas were raised in all material types with the Packaging Act. The systems must prove annually that they meet the quotas as part of the volume flow verification. The quotas apply to packaging that is licensed with dual systems and is collected by them on an annual average.

Extension of mandatory deposit and promotion of reusable containers

The Packaging Act extended the existing mandatory return and deposit of 25 cents for certain disposable beverage containers to include carbonated fruit and vegetable nectars (e.g. apple spritzers made from nectars) and mixed beverages with a whey content of more than 50 percent. An obligation to provide information for retailers (including mail order companies) was also introduced.

Both were basically obligated to clearly indicate single-use and reusable beverage packaging with clearly visible signs with the respective designation (on the shelf, during shipping)

Creation of a “central office”: extended registration and data reporting obligations, uniform market monitoring

The VerpackG creates a new authority “Zentrale Stelle Verpackungsregister” as a central control body. A registration obligation and packaging quantity reports form the foundation. Experts, auditors, tax consultants and certified accountants are also obliged to provide information about their activities.

Stronger alignment of license fees for packaging with ecological criteria

The Packaging Act obliges the dual systems (pursuant to Section 21 (1) of the Packaging Act) to create incentives for sustainable packaging production/design via the assessment of their license fees (participation fees), which they collect from the manufacturers and distributors of packaging for collection and recycling. In addition, minimum standards for recyclable design have been drawn up together with the Federal Environment Agency.

Option to introduce the recycling garbage can, strengthening of the municipalities’ design rights Design rights of the municipalities

The Packaging Act does not introduce a binding provision for the nationwide introduction of a recycling garbage can. To facilitate cooperation between the municipalities and the dual systems, the public waste management authorities were given additional influence and control options in the VerpackG.

Extended citizen information requirements

The dual systems have additionally taken over extended tasks in citizen information themselves.

Definition dual system: The Dual System refers to the near-household collection and disposal of used sales packaging in Germany. It follows the requirements of the German Packaging Act.

Interview with Winfried Batzke from the German Packaging Institute on sustainability in the packaging industry

PackPart: What are the benefits of sustainable packaging in general?

Winfried Batzke: Packaging is sustainable simply because it protects and stores products, the production of which consumes at least 10 times more CO2 than the packaging itself. On the other hand, however, materials, water and energy are consumed in the production of packaging. So whether packaging can be described as sustainable depends on factors such as material consumption or energy use on the one hand, but also on the specific conditions of its use, such as transport distance and reuse or recycling effort and disposal options on the other. There is therefore no such thing as “THE sustainable packaging”, but rather the optimum packaging for each individual application.

“If packaging manufacturers take a sustainable approach […], their chances in competition increase.

Winfried Batzke – Deutsches Verpackungsinstitut

Packpart: What advantages can packaging manufacturers create for themselves by using sustainable packaging solutions?

Winfried Batzke: If packaging manufacturers take a sustainable approach by saving material, using recyclable material, using recyclates or using renewable raw materials, and communicate their commitment in a credible way, their chances in competition increase. They are perceived as responsibly acting companies and are attractive for your customers and future employees.

PackPart: How can the use of sustainable packaging develop a unique selling proposition for a product?

Winfried Batzke: Since the protective function of packaging is assumed, there is the possibility of differentiation on the market through sensible sustainability strategies. Here, the right communication plays a major role. Packaging made of plastic, for example, can be highlighted as sustainable in individual cases just as much as packaging made of fiber-based materials, glass or metal due to its improved recyclability or low material input.

Industry trends towards environmentally friendly packaging

Which natural, ecological and sustainable packaging will we see more of in the coming years?

The company kompackt61 “(…) develops and sells sustainable packaging solutions made of jute for shipping sensitive goods, such as food and pharmaceuticals. The shipping boxes and insulated bags made of natural fiber are just as efficient as synthetic materials, but in contrast, they are biodegradable and climate-neutral,” says the start-up from Germany.

Styrofoam is one of the most commonly used packaging materials, especially for shipping. However, this material is anything but compatible for the environment. Styrofoam is neither biodegradable nor environmentally friendly in production. Around 1.5 liters of gasoline are needed to produce a single cube of Styrofoam. The American company Ecovative has found a way to replace Styrofoam.

An innovative process is used to produce innovative packaging in any shape from biological waste and fungi. The biological waste is first shredded and mixed with special fungal cultures (mycelium). After the mycelium has grown for several days, the mixture is shredded again and shaped into the final form. The growth is made possible by the biowaste, which serve as food for the fungi.

Within 5 days, the growth of the mixture has reached the desired shape. The compact mass is then subjected to another heat shock to stop the growth and make the material germ-free. Algae are also innovating the packaging industry in a completely natural and ecological way.

At less than 1 cent each, the invention of British start-up Ohoo is poised to revolutionize the liquid food market. The packaging is made from seaweed, is 100 percent biodegradable and edible. The special feature of the invention lies in the unusual type of packaging, which is modeled on the natural “packaging” of fruit.

The process of spherification forms a kind of waterproof skin around the liquid, comparable to the skin of a grape. Liquid foods could thus be sold in small portions like fresh fruit and make the production of billions of water bottles superfluous in the future.